China's lithium battery industry in 2022

Oct 11, 2022

China's lithium battery industry in 2022

Oct 11, 2022

Analysis of the development of China's lithium battery industry in 2022: downstream industry demand growth, the industry has become an investment hotspot

Development background: China's policies drive industry demand, favorable policies and market demand attract large amounts of capital to enter

In September 2020, China officially put forward the low-carbon development goals of "carbon peaking" by 2030 and "carbon neutral" by 2060 at the Federation, and the new energy represented by lithium batteries has become the development trend, with market demand gradually increasing; relevant government departments promulgated A series of favorable policies for the development of the lithium industry, under the dual role, as of the end of December 2021, China's lithium industry investment events amounted to more than 200, related investment amounted to 927.6 billion yuan, an increase of more than 300% year-on-year, compared with the 2018 related 47.7 billion yuan investment, the current related investment amount compound growth rate of 110%, for the development of the industry to inject vitality.

Industry supply: China's lithium industry is booming and it is a major global producer of lithium batteries

China is a large producer of lithium batteries, and the scale of China's lithium battery production will reach 342GWh in 2021, accounting for about 50% of global lithium battery production, and an increase of nearly 120% year-on-year. China's lithium market demand continues to grow at the same time, China's large number of lithium battery exports, 2021, China's exports of lithium batteries 5.358 billion, an increase of 44.27% year-on-year.

Industry materials: enterprises increase the research and development of relevant materials technology, and the supply of lithium resources in the market is tight

Lithium battery material research and development and production enterprises represented by Sansun are increasing investment in lithium battery-related material technology research and development projects, with a view to improving the performance of lithium battery products and enhancing the competitiveness of enterprises. At present, the supply of lithium resources in the Chinese market is insufficient and needs to be supplemented by imported lithium resources from abroad, further intensifying the battle for global lithium resources. According to the latest news, the relevant departments in China have indicated that they will increase the development of lithium resources to increase market supply and ensure the development of related industries.

Development trends: industry development prospects are good, enterprises need to increase lithium resources supply investment to enhance enterprise competitiveness

In 2021, the production and sales of new energy vehicles in China will increase by more than 1.5 times year-on-year, with 13.4% of the vehicles being electrically powered and the proportion of electrically powered new energy vehicles rising by nearly 8 percentage points year-on-year. The significant growth in sales of electric-powered new energy vehicles has led to the continuous development of the industry's upstream lithium battery manufacturing industry, with new energy vehicles becoming one of the main growth points of the lithium battery industry. China's lithium battery market demand is strong, but China's lithium resources are not abundant, making lithium resource supply the biggest constraint to the development of China's lithium battery industry.

Keywords: development environment, industry status, industry raw materials, development trend

I. Development background: China's policies drive industry demand, favorable policies and market demand attract large amounts of capital to enter

In September 2020, China formally proposed the low carbon development goals of "carbon peaking" in 2030 and "carbon neutral" in 2060 at the Federation, and in 2021, relevant departments in China promulgated the "double carbon In 2021, the relevant Chinese authorities promulgated two major programmatic documents under the "double carbon" system: the "Opinions of the Central Committee of the Communist Party of China and the State Council on the Complete and Accurate Implementation of the New Development Concept and the Carbon Neutral Work" and the "Carbon Neutral Action Plan for the Year 2030", formally defining China's future green and low-carbon development path. In response, relevant government departments have issued a series of policies related to green industrial development and environmental pollution, some of which involve energy restructuring and new energy development, proposing to vigorously research and develop new energy-related technologies with a view to gradually replacing high-carbon energy applications and reducing environmental pollution in the future.

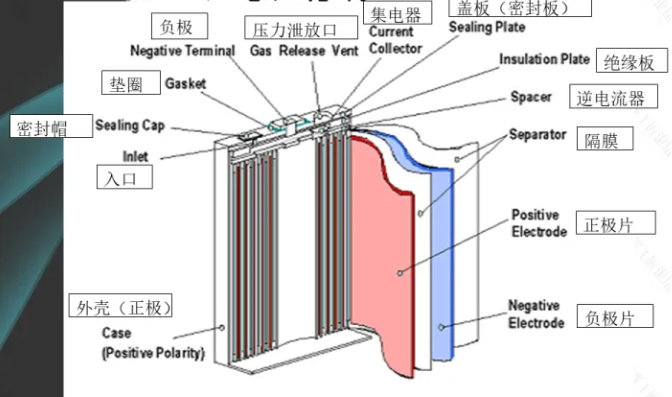

Batteries are an important energy storage device to reduce traditional energy consumption in modern society, but the traditional lead, mercury and other metal batteries have a general energy storage effect, low recycling rate and high difficulty in recycling, which will cause a considerable burden on the ecological environment. Lithium batteries have the superior characteristics of small size but high energy storage, which can extend the life of electronic devices, and lithium batteries do not produce harmful metals such as lead and mercury, whether in production, use or after disposal, and will not cause pollution to the environment. Lithium batteries have become the development trend of the battery industry, and the research of lithium battery-related products and technologies has become a hot spot for market investment.

Due to technical constraints, the lithium batteries currently produced in China are lithium-ion batteries. In order to regulate the industry standard, the relevant government departments in China revised the relevant regulatory standards in October 2021 and introduced the "Lithium-ion Battery Industry Specification Conditions (2021 this)" and the "Lithium-ion Battery Industry Specification Announcement Management Measures (2021 this)" two lithium battery industry specification standards. In China, China introduced other relevant policies explicitly mentioned to support the research and development of high-performance lithium battery technology breakthroughs.

Good news! " Small Giants" was honoured as a national specialized, new, and special enterprise by Guangdong Titans Intelligent Power.

Jul 18, 2023

Good news! " Small Giants" was honoured as a national specialized, new, and special enterprise by Guangdong Titans Intelligent Power.

Jul 18, 2023

Titans’ Forklift Charger Maintenance: Ensuring Efficiency and Longevity

Jul 10, 2023

Titans’ Forklift Charger Maintenance: Ensuring Efficiency and Longevity

Jul 10, 2023

The Dragon Boat Festival

Jun 22, 2023

The Dragon Boat Festival

Jun 22, 2023

Are you ready for the future of forklifts?

Jun 12, 2023

Are you ready for the future of forklifts?

Jun 12, 2023

China's lithium battery industry in 2022

Oct 11, 2022

China's lithium battery industry in 2022

Oct 11, 2022

Lithium Battery Industry Overview 2022 Lithium becomes the fastest growing commercial secondary battery

Sep 22, 2022

Lithium Battery Industry Overview 2022 Lithium becomes the fastest growing commercial secondary battery

Sep 22, 2022

What are the requirements for the selection of energy storage batteries? Why Lithium Iron Phosphate is preferred?

Sep 13, 2022

What are the requirements for the selection of energy storage batteries? Why Lithium Iron Phosphate is preferred?

Sep 13, 2022

Best Forklift li-ion battery charger in Guangdong

Jul 18, 2022

Best Forklift li-ion battery charger in Guangdong

Jul 18, 2022

Titan's All-in-one AGV

Jun 16, 2023

Titan's All-in-one AGV

Jun 16, 2023

Forklift Servicing / Maintenance

Jul 18, 2022

Forklift Servicing / Maintenance

Jul 18, 2022

Introduction to the Lithium Battery Industry in Southeast Asia

Jun 07, 2023

Introduction to the Lithium Battery Industry in Southeast Asia

Jun 07, 2023

Titans, your Lithium-ion batteries’ friends

May 29, 2023

Titans, your Lithium-ion batteries’ friends

May 29, 2023